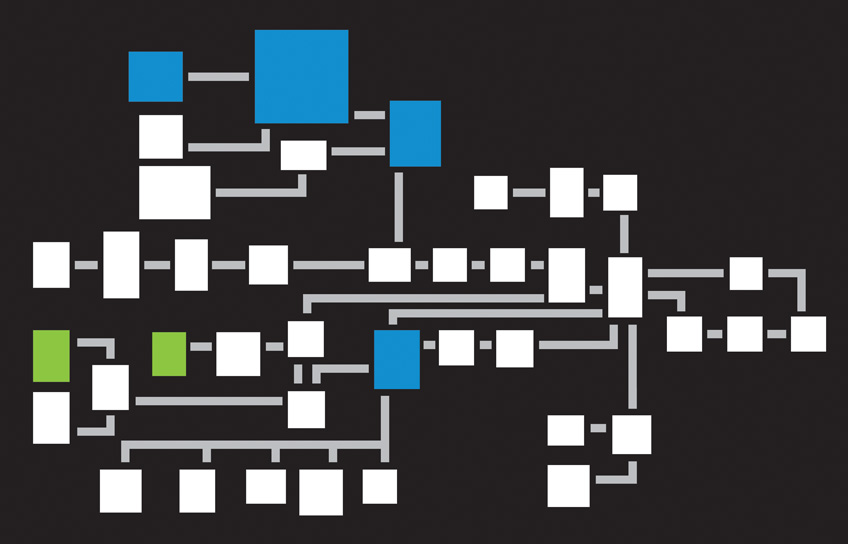

A usual first step on Lean and Agile Construction's projects is to prepare a Process Map of the critical operations required to achieve a near or medium-term milestones. We work with the onsite contractor and subcontractor's supervisors and foremen to truly understand and clarify the handoffs required for successful achievement of deadlines.

A process map is also called a flowchart, process flowchart, workflow diagram, business flow diagram or process flow diagram.

It shows who and what is involved in a process and can be used in any business or organisation and can reveal areas where a process should be improved. The core reason for mapping out your processes is that those organisations that perform the transformation of inputs into outputs well, generally manage to meet or exceed customer expectation.

Process Mapping in construction planning assists Pull Planning, Last Planner, and Takt planning teams to detail and visualise durations, inputs, handoffs, and decision points.

Specifically, process mapping

- Describes the flow of materials, information and documents

- Shows the various tasks contained within the process

- Clearly shows that the tasks transform inputs into outputs

- Indicates the decisions that need to be made along the chain

- Demonstrates the essential inter-relationships and interdependence between the process steps; and reminds us that the strength of a chain depends upon its weakest link.