Lean & Agile Construction’s goal is to leverage the opportunity that exists in construction to improve client value and sustainability of the sector.

Lean Construction consultancy, training, and consulting can identify and then dramatically reduce wasteful processes embedded within traditional delivery methodology.

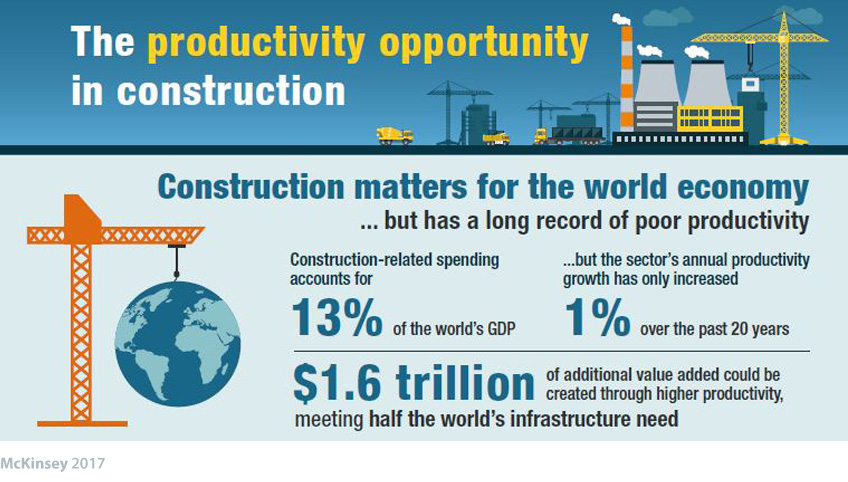

Global Construction Sector

A performing construction sector is integral for economic growth and makes a significant contribution to the GDP of many countries. To realise productivity gains in construction it is asserted that systemic change is required to transform the sector’s value offering to its clients. Prevailing construction research & literature indicates a fundamental gap pertaining to a next-customer and value focus, plus in the implementation of what is termed as “Real Lean”.

“The industry also loses a huge amount of value because of its low labour productivity, a shortcoming that has dogged the industry - whatever the location or stage of economic development - for decades”.

McKinsey 2017

Lean

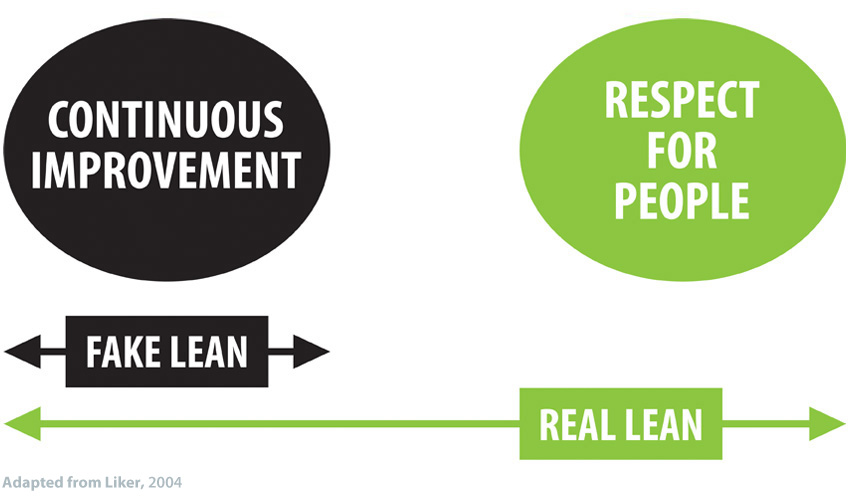

Numerous organisations attempted Lean implementation without creating the requisite Lean mindset, and primary reasons for failed transformations pertain to shortcomings in leadership understanding, management commitment and involvement, and people engagement and cultural issues. Lean provides a structured framework for continuous improvement and a set of tools to stabilise business processes and manage complex projects. True Lean is founded on Continuous Improvement and Respect for People in the delivery of Value.

Fundamentals of Lean

- To understand value from the customer’s perspective and to only take actions which deliver that value.

- Waste is disrespectful

to humanity - misuse of scarce resources

to individuals - adding unnecessary work

to clients - adds cost/time/stress - Become a learning organisation through relentless reflection and continuous improvement as a team. It entails continuously analysing the work and the team’s processes to improve them. Status quo is never acceptable.

- Lean is about inspiration and empowerment. People are empowered to affect decisions and the work itself which not only delivers better projects but leads to heightened satisfaction for all.

- Lean is about developing principles that are right for your organisation & diligently practicing them to achieve high performance. It is not about imitating the tools used by Toyota in a particular manufacturing process.

Lean Construction Management

The Lean approach to construction management is founded on a scientific method that extends from the objectives of a Lean production system. Lean Construction is therefore a different management approach from the conventional construction management system because it has a clear set of objectives for the delivery process; keeping a distinct customer-focus at project level and applying production control throughout the lifecycle of the project. Lean is relatively new to construction and regrettably much economic, time, social, and environmental waste occurs due to the lack of knowledge of the advantages Lean can bring to construction delivery.

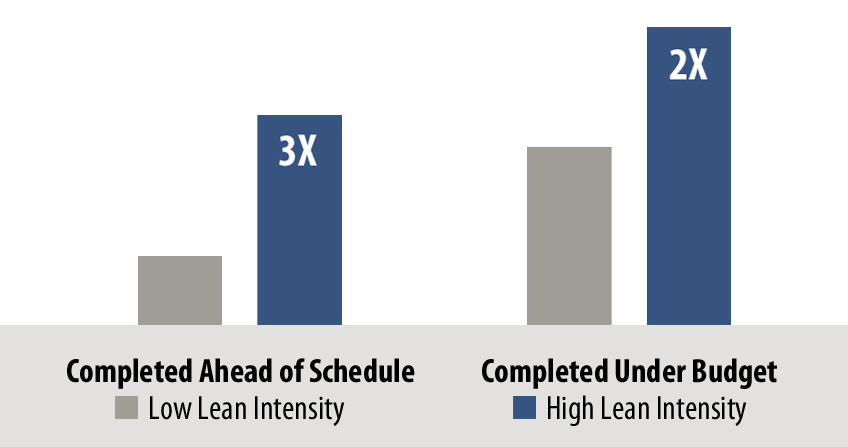

Lean Construction Institute research presents why Lean projects excel - Lean projects are three times more likely to be completed ahead of schedule and twice more likely to be completed under budget than traditionally managed projects.

Key advantages of Lean in construction are

- Safety - apply Lean thinking and concepts to eradicate unsafe practices and create a positive safety climate

- Productivity - use best-practice, research-developed, and tried and tested Lean Construction tools & techniques to improve production efficiency

- Quality - Reduce defects and rework by utilising Problem-Solving techniques and Right-First-Time mindset

- Cost - manage cost and improve team collaboration with Target Value Design

- Management Effectiveness - Leverage Lean Construction tools to eliminate wasteful processes and deliver value.

- Communication & Coordination - Adopt Agile & Scrum concepts and practices to enhance responsiveness & decision-making

- Sustainability - use Lean & Green methods to link economic continuous improvement to bettering the environment

- Marketing - Differentiate your construction company and project through Lean adoption

William Power

Lean Construction Ireland Commended TrainerWilliam Power is an experienced Construction Management professional with over 30 years of experience in project delivery across all sectors including residential, commercial, pharma, life sciences, marine, infrastructure, underground and overhead utilities.

William has worked across the entire construction supply and value chain from commencing as a site engineer and progressing to Site Manager, Project Manager, Contracts Manager and holding a number of Directorships ...

Lean Construction Ireland

Deliver Projects Better, Faster, TogetherWilliam Power is a member of Lean Construction Ireland (LCi), an all-island, independent, and voluntary not-for-profit association whose members passionately believe that Lean Thinking and Practices can enable and sustain enhanced effectiveness, efficiency, productivity, and profitability for the Irish Construction Sector, Clients, and Supply Chain.

William contributes to LCi with involvement in numerous working groups, for example, the Client Forum Pillar and the Capability Development Pillar, by contributing to course development.

LCi leads a community of learning and practice that promotes the application of Lean Thinking & Practices throughout