We help companies and projects start the Lean journey by providing the theoretical and practical foundations to understand & apply Lean principles, tools and methods. We assist mature teams progress and develop their Lean journey by providing ongoing coaching & consultancy to embed & standardise the continued use of Lean tools.

The objectives of the training are …

- To teach the concepts and practices of Lean Construction and how they can be applied to your project

- To ensure that you have a common understanding of the terms and concepts of Lean Construction so that you can effectively communicate with clients and colleagues

- To equip you with an process-focussed approach to project management that is based on scientific and systematic processes

- To provide you with the tools and concepts to improve your workflow and overall success of your projects.

Lean Education Modules

Module 1 Introduction to Lean & the need for Lean in Construction

Module 2 Lean Strategy Development & Deployment Workshop

Module 3 Production Planning and Control & Introduction to the Last Planner System

Module 4 Advance Topics in the Last Planner, Pull Planning, Takt-Time Scheduling

Module 5 Lean Tools for Decision Making and Continuous Improvement

Module 6 On-site improvements: 5S, Waste Walk, Direct Observations

Module 7 Agile and Scrum practices applied to Construction

Module 8 Target Value Design and Integrated Project Delivery

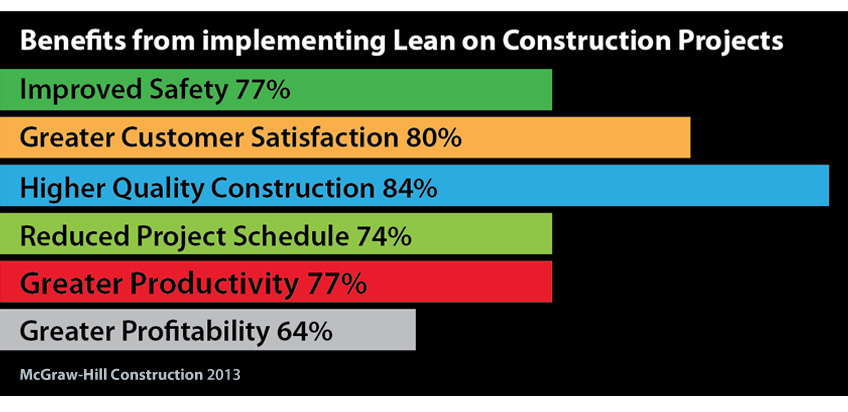

Lean Construction is becoming increasingly popular due to its direct benefits on safety, schedule, cost, and quality; Lean capability is now becoming an expectation as opposed to a ‘nice to have’.

The future of construction is Lean. The more management and employees understand and practice these concepts, the greater the opportunity for the sustainability and development of the company. Lean thinking and tools can solve some of the re-occurring problems on projects and offers a systematic approach to project management.

Implementing Lean needs innovation from bottom up (from the people who are doing the work everyday) and leadership & support from top management, who empower and encourage the use of Lean.